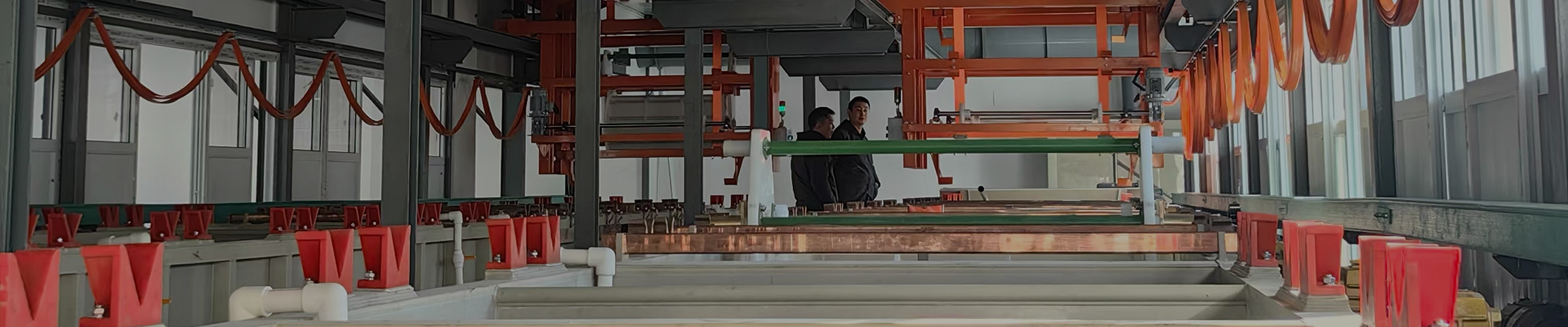

Gantry hanging plating production line

Gantry plating automatic wire operating system The equipment is controlled by the new Mitsubishi PLC and is equipped with a Mitsubishi frequency converter. The interface is simple and easy to learn, and the program can be modified remotely when accessing the network cable. Driving system The body is made of stainless steel and is not prone to rust. It is equipped with an imported transverse motor, the Ottonix sensor is positioned accurately. The hook is equipped with a sensor to prevent the flying bus from falling, ensuring stable driving operation. Plating fixture The new dual-connected clamp is adopted, which saves time and effort on operation and stabilizes the plywood. Vibrating device The 24V DC brushless low-voltage vibration motor is adopted to ensure safe production. The amplitude of the vibration motor can be adjusted according to the aspect ratio. The 485 communication output computer monitoring is used to monitor the motor operation parameters for all-round real-time monitoring, real-time fault alarm, and intelligent control is realized.

See MoreRing plating production line

Introduction to the ring vertical lifting line The ring vertical lifting wire is very different from the ordinary electroplating wire structure. The horizontal movement and lifting of the workpiece are no longer for a single groove, but the workpiece of the entire line is moving at the same time. The workpiece of the single groove is rising and moving horizontally, and then entering the next groove after falling. The workpiece of the plating groove and the multi-position potion tank moves continuously in the groove without lifting and lowering. This series of production lines has simple and simple mechanical actions, high efficiency and large output; the structure is tight, convenient for maintenance, and low equipment maintenance costs. Adopt human-computer interface touch screen management control, and relevant data can be modified according to production requirements (authorization required); The main electrical components are made of Japanese Mitsubishi, Omron and Schneider products; The lifting arm can be equipped with mounts or a rotating swing head to achieve 360° rotation of the workpiece in the plating tank; Equipment is widely used in hardware, bathroom, automotive ABS, electronics and other industries; it can achieve electroplating requirements such as nickel chromium plating, copper plating, abs copper nickel chromium and other industries.

See MoreGantry roller plating production line

Gantry plating automatic wire operating system The equipment is controlled by the new Mitsubishi PLC and is equipped with a Mitsubishi frequency converter. The interface is simple and easy to learn, and the program can be modified remotely when accessing the network cable. Driving system The body is made of stainless steel and is not prone to rust. It is equipped with an imported transverse motor, the Ottonix sensor is positioned accurately. The hook is equipped with a sensor to prevent the flying bus from falling, ensuring stable driving operation. Plating fixture The new dual-connected clamp is adopted, which saves time and effort on operation and stabilizes the plywood.

See Moreswitch

The switch is mainly used for the automatic lifting and transfer of electroplating hangers in electroplating production lines. Through components such as winches, hooks, slide rails, etc., combined with drive motor control, it realizes efficient transfer of electroplating hangers, reduces manual intervention, and improves production efficiency. Its core advantage lies in its compact structure and low cost, and is suitable for multi-station electroplating process. The main electrical components are made of Japanese Mitsubishi, Omron and Schneider products; The lifting arm can be equipped with mounts or a rotating swing head to achieve 360° rotation of the workpiece in the plating tank; Equipment is widely used in hardware, bathroom, automotive ABS, electronics and other industries; it can achieve electroplating requirements such as nickel chromium plating, copper plating, abs copper nickel chromium and other industries.

See More